Why Automotive OEMs Prefer Forged Components

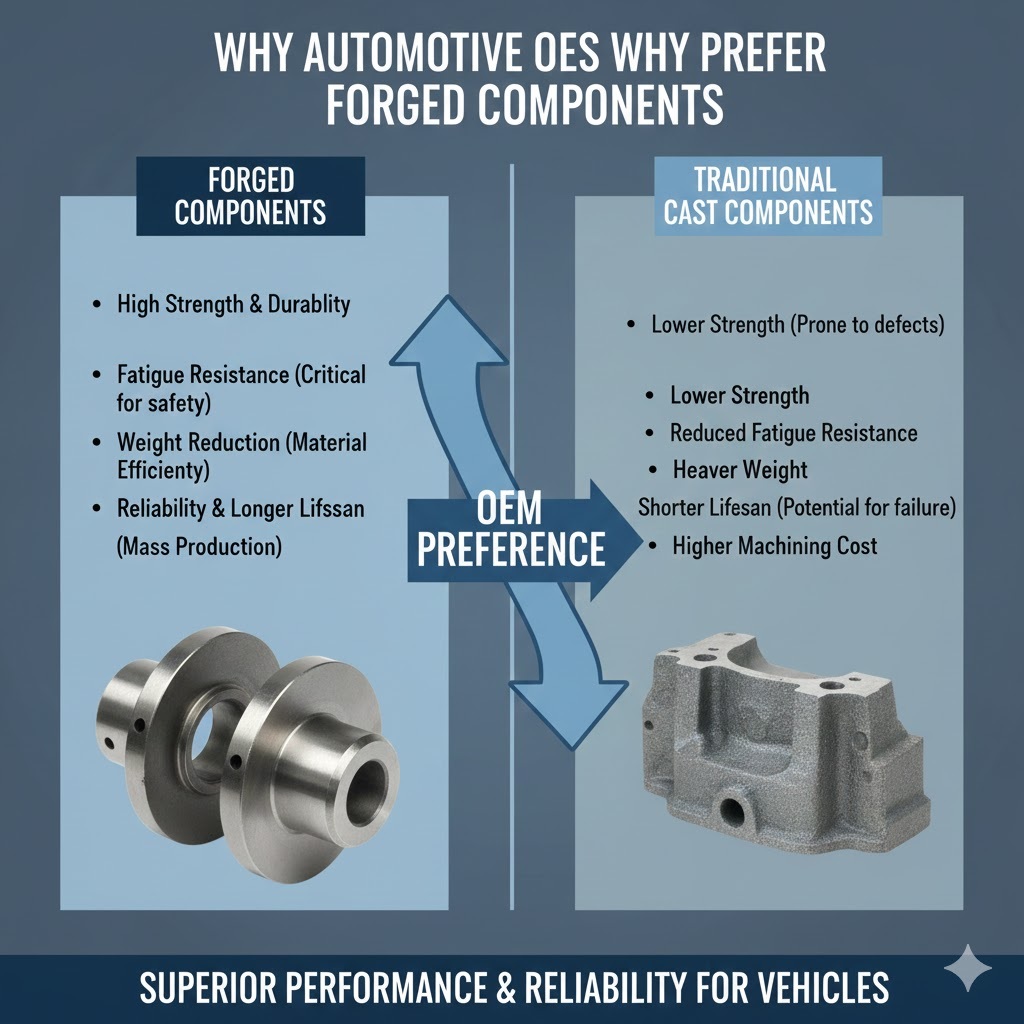

In the automotive industry fortune favors the brave and a wrong move in a sourcing plan invariably turns from a minor administrative error to the difference between the successful launch of a high-performance vehicle and a costly recall fiasco. While it is understandable that one may be tempted to cut production costs by switching critical components like transmission gears or steering knuckles from forged parts to supposedly “high-quality” castings, the technical reality often proves to be the exact opposite. For safety-critical systems, forged automotive parts are not just an option but a basic engineering requirement for structural integrity.

Nowadays, a lot is being discussed about forgings versus castings and machining for parts fabrication. This post details some of the reasons why Original Equipment Manufacturers (OEMs) across the globe and India are going back to the forging route more and more for their component manufacturing needs and also offers useful frameworks to handle the complex Indian industrial market.

Structural Integrity Science: Why Forging is Superior

A single glance can’t tell how a metal piece was made – cast, cut, or hammered into form. Truth lives beneath, hidden inside its microscopic layout. Shaping metal through force happens while it stays solid, squeezed under massive pressure to reach its final figure. Unlike methods where molten material fills a cavity, this method stretches the inner fibers, matching them precisely to the object’s outline.

A chunk of ice versus strands knotted close – this shows the contrast. Hitting a casting exposes tiny air pockets inside. These gaps trap force, making breaks happen fast. Forged pieces differ. Their grains run without interruption, weaving through the shape.

This leads to:

- Greater Impact Resistance: The capability to withstand sudden shocks without fracturing.

- Better Fatigue Life: Forged parts can often be subjected to several times the number of load cycles compared to cast parts before the first signs of wear appear.

- No Internal Defects: Since the metal stays solid throughout the process, problems like gas porosity or shrinkage voids – which are quite common in casting – are almost non-existent.

India Market Dynamics: Why OEMs Transition

India automotive industry is today the largest user of forged products in the country and the Lancer of the Industry. Undergoing transition to Bharat Stage VI (BS-VI) emission norms and gearing for unleashing global stringent emission standards, the upgradation of mechanical hardware in power train components is at its zenith.

Electric Vehicles (EVs) transition indeed highlights the case. An erroneous belief is that EVs do not incorporate forgings simply because the latter have no internal combustion engines. Actually, the instant torque of the electric motor subjects gears, axles, and shafts to extremely high levels of stress. OEMs, thus, are now utilizing precision cold forging in EV drivetrains since cold forging bestows chances to hold tight the dimension tolerances at the same time maintaining a quality level capable of handling “always-on” motor power delivery.

Moreover, the craze for “lightweighting” to achieve higher fuel efficiency (or EV range) has privileged the use of forged automotive parts. They feature a much higher strength-to-weight ratio; it is possible to design a likewise lightweight part that structurally measures up to the safety standards of a cast part or even surpasses it in safety.

Guidelines for Sourcing: An Indian OEM Framework

Finding a trustworthy partner amidst the Indian manufacturing B2B industry is no easy task as there is a huge gap between the highly organized and technology-driven sector on one hand and street vendors and cottage industries on the other which often take shortcuts. Here is a checklist to ensure an audit trail record of quality and commitment from a prospective forging partner.

1. Insist on Full Traceability of Raw Materials

Indian market has some vendors who attempt to adulterate their low-cost products by mixing scrap metal with high-grade alloy steel. This is a critical failure point.

- Actionable Step: Never take a final test certificate at face value only and ask for the original mill certificates and heat numbers for the raw billets.

- Confirmation: A world-class company will have a “batch-wise” record by process step of the components, starting from raw materials to shipment including every hammer strike on the metal.

2. Assess Completely the Production Environment

The dimension of the forging press ( e. g., 2,500-ton hammer) alone cannot decide the quality of a forged part.

- In-House Tooling: Prioritize manufacturers that have in-house tool design and development capabilities. If a manufacturer is outsourcing their dies, it will be a problem for the lead times and the quality control becomes fragmented.

- Secondary Operations: A local supplier without proper heat treatment and CNC machines for final tolerances might have to send the part in a different location causing the rise of metallurgical inconsistency risk problems.

3. The Automation and Consistency Test

Consistency is the key player in automotive high-volume production. Human variability in heating or striking can cause irregular grain flows.

- Actionable Step: Check out automated induction heating and robotic handling during the factory inspection. With automation, all billets are heated and struck at the exact same temperature and pressure, which is the key to uniform micro-structural properties over an entire million-unit run.

Total Cost of Ownership Analysis

It is normal for procurement folks to be looked at different quotes and be surprised if the price difference is around 15% or more. However, if the lowest bidder is chosen, it is also most likely the case that high “hidden” costs will be incurred in the future.

- Workability is Highly Improved: Because forged parts have a more compact and homogeneous structure, they are generally faster and easier to machine than cast parts. Thus, the CNC cutting tools experience less wear and there will be fewer scrapped pieces during the final finishing stage.

- Less Material Waste: Forging involves forming a part that is very close to the final shape of the part thus utilizing up to 90% of the material. In contrast, when a part is machined from a solid bar, a lot of waste is generated which is not only bad for the environment but also costly.

- Risk Mitigation: The cost of failure of just one component in the steering or braking system when calculating the liability, loss of brand value, and recall logistics is extremely high. In this sense, choosing forged components is like taking out an insurance policy against a disastrous failure.

What Next: Sophisticated Alloys and Digitization

India’s forging industry has for long been mistaken as a “low cost” manufacturing hub only. Today it is undergoing transformation and several Tier-1 suppliers are experimenting with advanced aluminum and titanium alloys to meet the demand of high-end global exports. We also witness the integration of “Digital Twins” alongside AI-optimized heat treatment cycles, thereby enabling even more precise control of metal properties.

Simply put, it seems that the days of “good enough” casting for critical parts are numbered. As vehicles become more and more performance-oriented, the error margin gets less and less.

Conclusion

Sourcing within the Indian industrial arena needs a good mix of technical auditing and relationship nurturing. A supplier ought to be seen more as a technical partner than merely a vendor. An expert manufacturer is capable of providing design-for-manufacture feedback which means he can point out to you minor changes in the part geometry that might result in improved grain flow or longer die life.

When it comes to making a sourcing choice for forged automotive components, select those that have their own process going. Check certifications (IATF 16949 is mandatory for automotive), check the origin of the materials and make sure the process it is sufficiently automated. OEMs simply cannot go wrong with these checks, which ensure that the heart of their vehicles and their brand are rock-solid.