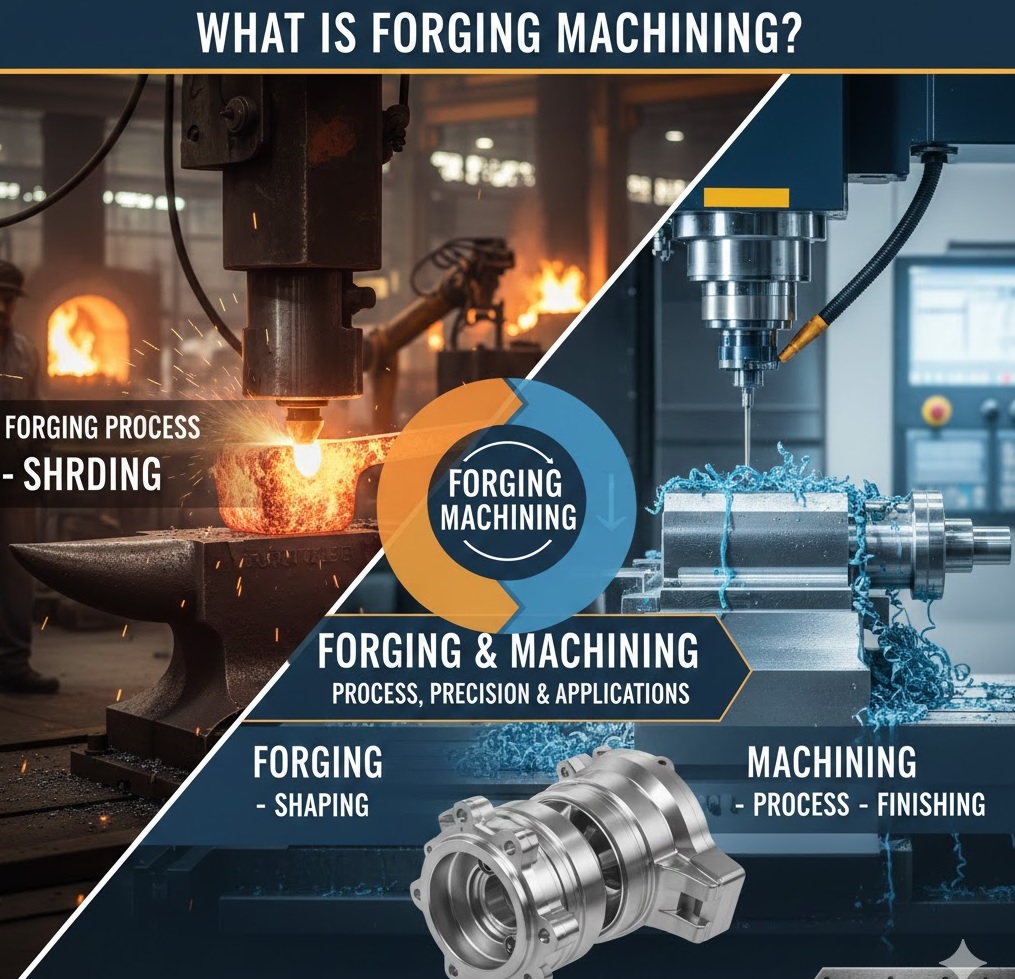

What Is Forging Machining? Process, Precision & Applications

Machining after forging is a secondary manufacturing method that creates final dimensions requiring precise tolerance and finish using a variety of different machine tools (e.g., lathe, mill, drill, etc.). Forging causes deformation of metal by compressive forces that increase its strength and improve the flow of the grain structure. The machining processes used, such as turning, milling, drilling and grinding, will remove excess material left over during the entire forging process, so that the finished product meets the design specifications and fits properly with other components in an assembly. Machining after forging provides components with the superior mechanical properties created during forging and will also ensure that those components will be accurately assembled together. Forging and machining combined can be used for manufacturing components that are typically found in many different industries including automotive, aerospace, oil & gas and heavy engineering. Critical characteristics for these industries include high strength, dimensional accuracy and reliability.

How forging machining ensures precision manufacturing?

The process of forging machining guarantees precision manufacture by creating forged components to the precise dimensions, tolerances, and surface quality required for critical applications. The forging process allows us to enhance the internal strength and grain structure of the metal, and then we utilize advanced machining operations like CNC turning, milling and drilling to create consistently accurate and repeatable products after forging has occurred. Controlled removal of material through machining will correct for any small deviations in dimensions created during the forging operation, it will provide for a proper alignment of all features, and it will yield smooth and functional surfaces. So as a result of those processes forging machining provides very high-performance components that fit precisely, function reliably, and have consistent quality—this makes them especially appealing to sectors where precision and durability are essential.

Applications of forging machining

The use of forging machining occurs in all industrial sectors and requires parts with a high level of strength, accuracy, and reliability for their intended purpose. In the automotive industry, for instance, forged parts such as crankshafts, connect rods, gears, and axles must endure cyclical loads and vibrations from vehicle operation and must be manufactured using forging/machining processes. The aerospace industry requires applying forging machining to produce structural components (forged/machined parts), landing gear components (forged/machined parts), and engine mast as they have high requirements for both quality and safety. The oil and gas industries also require forging machining to manufacture components such as flanges, valves, fittings and pressure-bearing components that operate in high-pressure and high-temperature environments. The industries of heavy engineering, power generation, construction machinery, and industrial manufacturing consider forging machining a vital manufacturing process in producing durable manufactured components with accurate dimensions and repeatable performance.

Conclusion

To sum up, power machined forging is an essential method of modern manufacturing that utilizes the power of forging to make solid, reliable components with high performance characteristics (and dimensional and surface finish accuracy) by combining both forging and advanced machining technologies into one system. By eliminating variation, improving consistency, and providing dependable performance even under extremely challenging conditions, power machined forging makes it possible to produce value added parts in many of today’s most demanding industries. Because power machined forging can provide strength, form, reliability, and consistency, it is the fastest growing manufacturing process for parts that must not be compromised in performance and reliability.