The Evolution of Automated Packaging: From Manual to Smart Systems

Packaging technology has undergone a remarkable transformation over the years, evolving from simple manual processes to sophisticated smart systems that integrate AI, robotics, and data analytics. This evolution has not only improved efficiency but also enhanced product safety, quality, and customization options. In this article, we will explore the journey of packaging automation and how it has shaped the industry.

From Manual Processes to Mechanization

The earliest packaging methods were entirely manual, relying on human labor to assemble, seal, and label products. This approach was labor-intensive and prone to errors, making it unsuitable for large-scale production. With the onset of the Industrial Revolution, the need for faster and more consistent packaging processes grew, prompting the development of mechanized systems.

Mechanization introduced tools and machines that could handle repetitive tasks with greater accuracy and speed. Conveyor belts, sealing machines, and basic automated fillers became commonplace in manufacturing facilities. This shift enabled companies to increase productivity, reduce costs, and maintain consistent quality. However, while mechanization was a significant improvement, it still required human oversight and intervention.

The Rise of Automated Systems

The next phase of evolution involved the transition from mechanization to automation. Automated systems emerged in the mid-20th century, powered by advancements in electronics and computer technology. Packaging lines were equipped with programmable logic controllers (PLCs) and sensors to enhance precision and reduce human intervention.

Automation revolutionized industries by providing greater control over production lines. Processes such as sorting, filling, sealing, and labeling could now be carried out with minimal human involvement. This increased efficiency, reduced labor costs, and enhanced consistency. Packaging machine manufacturers in Chennai began to offer a wider range of equipment designed to meet specific industry requirements.

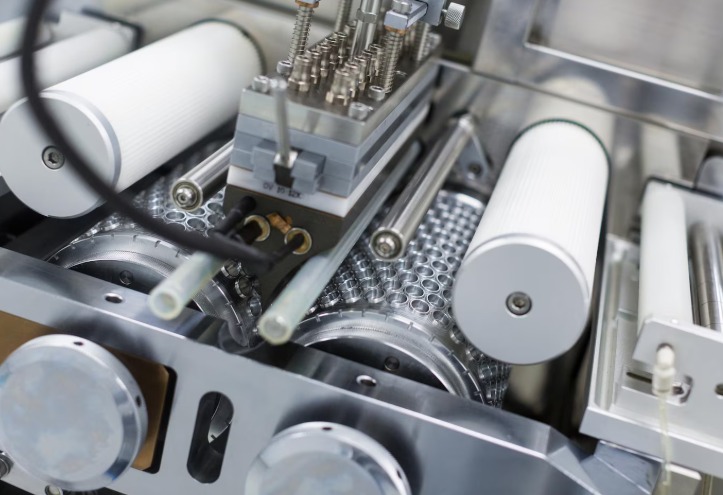

The Integration of Robotics

By the late 20th century, robotics became an integral part of automated packaging. Robots offered enhanced flexibility and precision, making them ideal for complex tasks such as product sorting, palletizing, and packaging fragile items. Their ability to operate continuously with minimal downtime further improved productivity.

The integration of robotics also allowed manufacturers to customize packaging processes according to specific product needs. Collaborative robots, or cobots, emerged as a solution for tasks that required interaction between humans and machines. This collaboration improved safety and efficiency, paving the way for more adaptable and intelligent packaging systems.

Emergence of Smart Packaging Systems

The advent of the Internet of Things (IoT) and artificial intelligence (AI) brought about the era of smart packaging systems. These systems utilize sensors, data analytics, and real-time monitoring to optimize packaging processes and ensure quality control. With smart systems, manufacturers can detect anomalies, track performance, and make data-driven decisions.

Smart packaging systems also provide enhanced traceability, allowing companies to monitor products throughout the supply chain. This level of visibility ensures compliance with regulatory standards and improves overall efficiency. Moreover, predictive maintenance, enabled by AI, helps prevent costly downtime by identifying potential issues before they occur.

The Role of Digitalization

Digitalization has become a driving force in the evolution of automated packaging. Through cloud computing and advanced analytics, manufacturers can achieve greater connectivity and control over their packaging lines. Data from various sources can be integrated to streamline processes and enhance productivity.

Digital twin technology, for instance, allows companies to create virtual replicas of packaging systems to simulate performance and optimize efficiency. Additionally, the use of blockchain technology ensures transparency and security in supply chain management.

Sustainability and the Future of Automated Packaging

As industries move towards sustainability, automated packaging systems are also evolving to minimize environmental impact. Energy-efficient machines, recyclable packaging materials, and waste-reduction technologies are becoming standard practices. Automation helps optimize material usage and reduce carbon footprints, aligning with global sustainability goals.

Looking ahead, the integration of AI and machine learning will further enhance the capabilities of automated packaging systems. Manufacturers will continue to innovate, developing systems that are not only efficient but also environmentally responsible. As technology advances, the focus will shift towards creating packaging solutions that cater to both business efficiency and ecological preservation.

Conclusion

The evolution of automated packaging from manual processes to smart systems has been a journey of innovation and adaptation. From simple mechanized tools to sophisticated AI-driven systems, each phase has contributed to making packaging more efficient, reliable, and versatile. As industries continue to embrace digitalization and sustainability, the future of automated packaging looks promising.

If you are searching for advanced solutions from packaging machine manufacturers in Vasai, the industry offers a wide range of options tailored to meet diverse needs. Understanding the evolution of packaging technology is essential for making informed decisions that align with your business goals.